The Flexby project is dedicated to advancing biofuel production through innovative technologies and processes. One of the key focuses of the project is the efficient valorisation and conversion of industrial and domestic biogenic wastes into biofuels using non-carbon emitting technologies like microwave pyrolysis treatment.

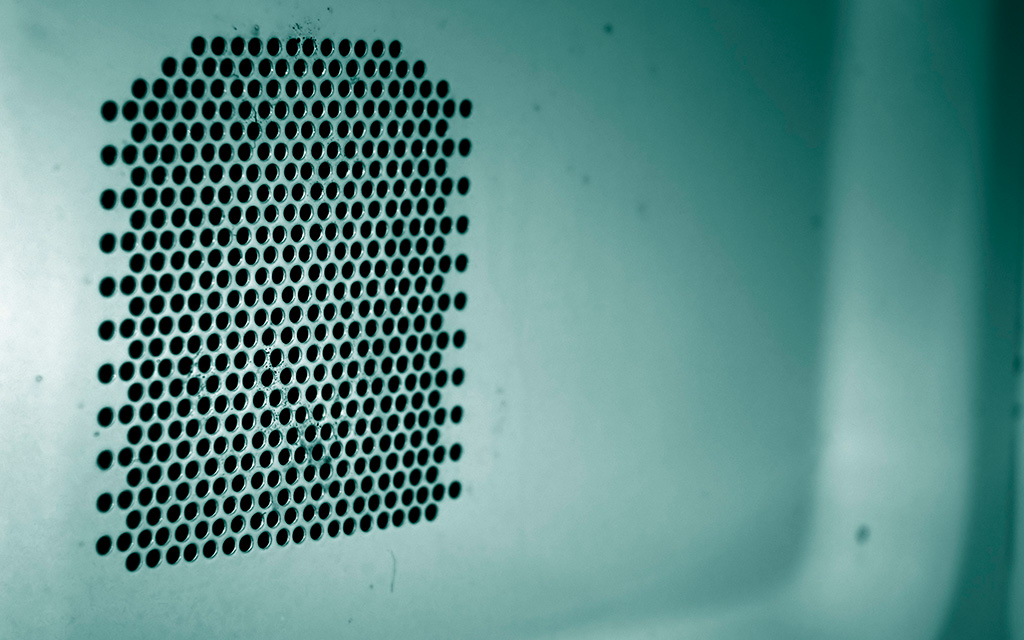

The microwave pyrolysis process in the Flexby project is a cutting-edge technology that involves the thermal decomposition of organic materials in the absence of oxygen using microwave radiation. This process offers advantages such as rapid heating rates, precise temperature control, and the ability to process a wide range of feedstocks efficiently. The system includes components like water-cooled magnetrons, a launcher, a water-cooled isolator, a filament transformer, and bidirectional couplers to ensure efficient and controlled processing of the feedstock.

The integration of microwave pyrolysis allows for customisation of process parameters like temperature, residence time, and heating rates to produce various biofuels such as bio-jet, biodiesel, marine biofuel, and bio-hydrogen. The process involves exposing the feedstock to high-frequency electromagnetic radiation, typically in the microwave range, causing the molecules to vibrate and generate heat through molecular friction. The absence of oxygen in the process prevents combustion and enables the production of biofuels with high energy content and low oxygen content. Operating conditions are fine-tuned to maximize the production of bio-oil, biochar, gas, and other valuable products while minimising waste generation.

The microwave pyrolysis process can reach high heating rates and temperatures, ensuring complete conversion of the biomass into desired products with high energy efficiency. Overall, microwave pyrolysis represents a state-of-the-art technology crucial for the efficient conversion of biogenic wastes into valuable biofuels within the Flexby project.