The FLEXBY project is paving the way for advanced biofuel technologies through the use of cutting-edge techniques like microwave pyrolysis and hydrogen-free hydrodeoxygenation. Recently, FLEXBY released a report titled "Physicochemical Sheet for Biomass Feedstock", which delves into the suitability of different biomass feedstocks for these technologies. This report, led by CSIC-INCAR, examines six distinct bio-waste samples from industrial wastewater sources to determine their viability as raw materials for biofuel production.

Analysing Bio-waste for Biofuel Potential

The report opens with a breakdown of roles within the FLEXBY consortium: CSIC-INCAR is responsible for physicochemical analyses, while Fricke and Mallah assesses the dielectric properties of feedstocks, a key factor in determining their efficiency in microwave processes. The six bio-waste samples tested include:

- 2 microalgae-based residues from urban wastewater,

- 2 macroalgae processing sludges, and

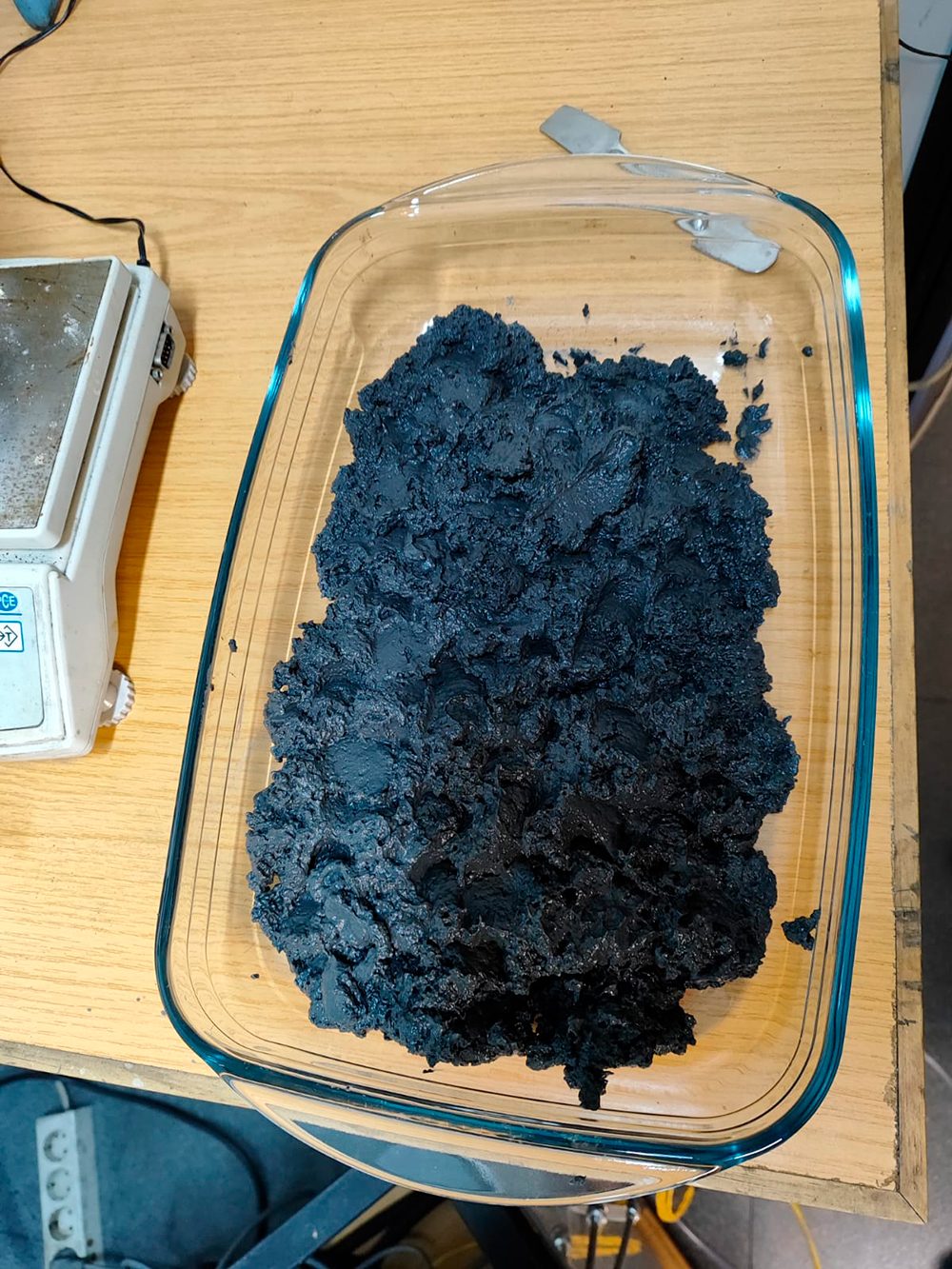

- 2 oily sludges from the dairy industry.

Each sample underwent rigorous testing for essential factors such as water content, elemental composition (carbon, hydrogen, nitrogen, sulphur, oxygen), ash and volatile matter content, chlorine and potassium levels, heating value, ash melting point, and thermogravimetric properties.

Key Findings: Which Feedstocks Hold Promise?

One standout discovery is the variability in ash and volatile matter content across the samples. The microalgae-based residues and oily sludges from the dairy industry demonstrated low to moderate ash content (13-24%) and high volatile matter (60-80%), both indicators of suitability for biofuel production. In contrast, the macroalgae-based feedstocks exhibited high ash content (60% and 41%) and low carbon content (18% and 28%), making them less promising for cost-effective biofuel production.

The Chlorine Factor: Protecting Equipment and Processes

The report also emphasises the role of chlorine content in feedstocks, as high chlorine can damage pyrolysis equipment. One of the dairy industry feedstocks recorded the lowest chlorine content (0.015%), safely below the corrosion risk threshold. Conversely, the macroalgae feedstocks contained higher chlorine levels, which could pose challenges in long-term equipment maintenance.

Thermogravimetric and Dielectric Analysis: Confirming Microwave Processing Suitability

To further assess feedstock performance, a thermogravimetric analysis was conducted, showing that an optimal pyrolysis temperature, at least for conventional pyrolysis, of 600°C or higher would be most effective. All samples displayed favourable microwave absorption qualities, with dielectric measurements around a loss tangent of 10⁻², signifying effective energy absorption. The macroalgae feedstocks, despite their excellent dielectric properties, remain less suitable overall due to their higher ash and lower carbon content.

Conclusion: Selecting the Best Biomass Feedstocks for FLEXBY

In summary, the report has identified 4 biomass samples – 2 microalgae-based residues from wastewater and 2 oily sludges from the dairy industry - as viable candidates for the FLEXBY project’s objectives. Of these, one of the dairy industry feedstocks shows the greatest promise, boasting the lowest ash content, highest carbon content, and the highest proportion of volatile matter, making it the most promising option for biofuel production.

This comprehensive feedstock analysis provides crucial insights that will guide the FLEXBY project’s next steps, ensuring the selection of the most efficient and effective raw materials for advancing biofuel technology. With this foundational knowledge, FLEXBY is well-positioned to advance to the next stages of the project.

You can view and download the full report here >